Last updated on January 7th, 2026 at 11:24 am

Introduction

In precision manufacturing, a staggering 30% of cost overruns can be traced back to initial material selection errors, leading to subpar part accuracy and delayed deliveries. A typical costly example is mistakenly choosing standard stainless steel over free-machining steel, which can increase tooling costs by 40% and disrupt production schedules. The core issue lies in traditional methods that view material properties in isolation, ignoring their systemic relationship with machining parameters and tool life.

This article provides a data-driven solution, revealing how material characteristics holistically impact cost, precision, and production efficiency, and introduces a systematic selection framework aligned with ISO standards. The following sections will break down the critical dimensions of material selection to optimize decision-making processes.

How Does Material Hardness Directly Impact CNC Turning Precision and Tool Wear?

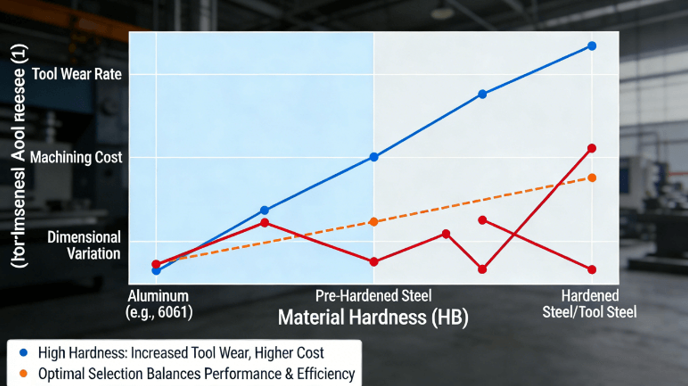

Material hardness is one of the most direct and significant properties influencing the CNC turning process. It acts as a double-edged sword, requiring a delicate balance between precision, tool life, and machining efficiency.

The relationship between hardness and dimensional accuracy is a constant trade-off. High-hardness materials, such as hardened steels, offer excellent wear resistance but generate extreme resistance against CNC lathe tools, increasing cutting forces. This can induce elastic deformation in the machine and workpiece, leading to dimensional fluctuations up to ±0.1mm. Conversely, low-hardness materials like aluminum are easy to cut but prone to thermal deformation under machining heat, equally compromising stability. Adherence to stringent standards like ASME Y14.5 is crucial for precision control.

The Accelerating Effect of Hardness on Tool Wear

- Abrasive Wear Intensification:

Hard particles within a material or its overall high hardness act like sandpaper, rapidly wearing down the tool’s cutting edge. When machining hardened steel, tool life may be only one-tenth of that when machining low-carbon steel. - Cutting Heat and Diffusion Wear:

Machining high-hardness materials generates more heat, which can cause diffusion between the tool tip and the chip material, softening and depleting the tool coating and substrate.

The key is matching the material to the process. For high-hardness materials, selecting more wear-resistant tool materials (like CBN, ceramic coatings) and optimizing cutting parameters is essential. Strategic CNC turning parts material selection, such as opting for pre-hardened or free-machining steels when performance requirements allow, can significantly reduce unplanned tool changes, maintaining production continuity

What Are the Top 3 Material Choices for High-Volume vs. Low Volume CNC Turning Parts?

Production volume strategy is a core commercial driver for material selection. Different batch sizes impose distinct requirements on cost structure, supply stability, and processing efficiency.

- Preferences for High-Volume Production:

For projects requiring long-term, stable output of thousands to tens of thousands of parts, selection prioritizes stability, predictability, and total cost of ownership. - 17-4PH Stainless Steel:

Offers high strength and hardness after precipitation hardening, with minimal heat treatment distortion and excellent consistency, ideal for high-volume structural components. - Free-Cutting Steel (e.g., 12L14):

High material machinability enables the fastest cutting speeds and longest tool life, achieving the lowest per-unit machining cost. - 303 Stainless Steel:

An addition of sulfur or selenium improves machinability compared to 304, making it a common compromise for parts requiring corrosion resistance and controlled processing costs. High-volume production should be underpinned by quality management systems like ISO 9001 to ensure batch-to-batch consistency. - Strategies for Low-Volume/Prototype Production:

For low volume CNC turning parts or R&D prototypes, the focus shifts to production efficiency, material availability, and flexibility. - 6061 Aluminum Alloy:

Lightweight, easy to machine, cost-effective, and readily available, enabling rapid machining speeds and good surface finish for fast iteration. - 1018 Low-Carbon Steel:

Good strength and machinability, low cost, and easy procurement make it suitable for functional prototypes. - Delrin (POM):

This engineering plastic can be machined to tight tolerances with no burrs, often used for prototypes of gears and bearings requiring low friction. A proficient CNC turned parts manufacturer will offer coherent support from prototyping to production.

How Can Machinability Ratings Slash Production Costs by 30% in Custom Turned Parts?

The machinability index is a quantitative measure of how easily a material can be cut, directly influencing machining time, tool costs, energy consumption, and surface quality. It is paramount for controlling the production efficiency of custom turned parts.

Comparing 12L14 free-cutting steel (machinability ~90%) with titanium alloy (e.g., Ti-6Al-4V, machinability ~40%) reveals stark differences: machining titanium may require reducing cutting speeds to a quarter of those for steel, with tool wear rates 5-10 times faster and higher consumption of coolant and power. This disparity can lead to a multi-fold increase in per-part processing costs.

Enhancing machinability impacts more than direct costs. Selecting easier-to-machine materials or states, combined with optimized cutting parameters, reduces energy consumption per part, aligning with green manufacturing principles. Efficient machining also means less waste generation. Implementing scrap recycling strategies further reduces material costs and environmental footprint. Professional CNC turning services providers can achieve near-zero-waste production through material and process optimization .

Why Does Material Stability Dictate Long-Term Performance in Precision Components?

For high-value CNC precision turned parts, short-term machining accuracy is just the beginning; long-term dimensional and performance stability under complex operating conditions is the ultimate test. Material stability primarily involves stress relief and thermal expansion.

Consider an aerospace engine component: if the raw material contains internal residual stresses that release during machining or gradually through temperature cycles in use, it can cause slow, micron-level (e.g., 0.05mm) deformation, potentially leading to system failure. Similarly, if a material’s thermal expansion coefficient mismatches with mating components, significant thermal stress or clearance changes can occur at operating temperatures.

Therefore, assessing microstructural stability, residual stress levels, and thermal expansion coefficient at the selection stage is critical for precision, long-life parts. Following stability testing methods recommended by standards bodies like NIST provides a scientific basis. For stringent industries like aerospace, partnering with a supplier holding AS9100D certification ensures material traceability and process control, mitigating long-term performance risks .

How Do Leading Suppliers Optimize Material Supply Chains for Fast Turnaround?

In today’s competitive market, delivery speed is a key differentiator. Top-tier CNC turning parts supplier have optimized their material supply chains as a critical lever for shortening lead times.

- Early Design and Process Involvement:

Expert suppliers engage during the client’s design phase, providing Design for Manufacturability (DFM) feedback. They can suggest alternative materials that are functionally equivalent but more readily available or easier to machine, or recommend standard stock sizes, preventing delays from long procurement cycles for special materials.

Digital and Transparent Supply Chain

- Real-Time Inventory and Forecasting Systems:

Digital platforms integrated with major material distributors enable real-time visibility and management of common material stocks. Demand forecasting based on historical data allows for proactive stocking, ensuring key materials are “always available.” - Supplier Collaboration and Certification Network:

Establishing direct, stable partnerships with certified raw material producers shortens procurement chains and ensures immediate transfer of material certificates, eliminating intermediate verification steps. - Certification-Backed Traceability and Reliability:

In sectors like medical devices, the selection, storage, and handling of materials must be flawless.

For a medical component project, JS Precision utilizes a digital platform for supply chain transparency, supported by its ISO 13485 quality management system. This ensures full traceability from raw material to finished product, accelerating internal processes and drastically reducing compliance risks and project delays

What Are the 5 Critical Mistakes to Avoid When Selecting Materials for CNC Turned Parts?

Avoiding common pitfalls is the first step toward sound material selection. Here are five critical errors to guard against:

- Ignoring the End-Use Environment:

Focusing only on room-temperature mechanical properties while neglecting actual operating conditions like temperature, corrosive media, or wear. - Over-Specifying Performance Metrics:

Selecting high-performance materials (e.g., titanium or nickel-based alloys) far exceeding actual needs, leading to exorbitant costs and machining difficulties. - Overlooking Inventory and Procurement Costs:

Specifying non-standard sizes or rare materials faces long lead times, high minimum order quantities, and storage pressures. - Sacrificing Machinability for Strength:

Choosing high-strength but difficult-to-machine materials causes tool costs and production time to spiral out of control, harming production efficiency and cost precision. - Failing to Consider Post-Processing and Assembly:

Not accounting for the heat treatment, welding properties, or compatibility of the selected material with other components creates challenges downstream.

Using a checklist that incorporates functional needs, process constraints, and commercial considerations is recommended for systematic evaluation. A thorough assessment of CNC turning parts material selection is the most effective investment to avoid costly rework and delays.

Conclusion

Material selection is not a simple comparison of performance parameters but a strategic lever in CNC turning parts manufacturing that influences the entire system. By systematically evaluating and balancing hardness, machinability, stability, and supply chain factors, businesses can simultaneously optimize cost structures, improve dimensional accuracy, and maximize production efficiency, gaining a competitive edge.

Author Biography

This article was authored by a team of precision manufacturing experts. Their organization holds industry-authoritative certifications including ISO 9001, AS9100D, IATF 16949, and ISO 13485, specializing in high-precision CNC turning parts manufacturing. For customized material solutions and an instant quote, visit their CNC turning services .

FAQ

Q: How does material hardness affect surface finish in CNC turning?

A: Excessively high material hardness requires slower cutting speeds and increased cutting force, potentially causing tool vibration or built-up edge, leaving chatter marks or roughness on the machined surface. Optimal material selection and cutting parameters can ensure stable achievement of surface roughness below Ra < 1.6μm per standards like ISO 1302.

Q: What material is best for low-volume, high-precision medical components?

A: For low-volume, high-precision medical components, 316L stainless steel is an ideal choice. It offers excellent biocompatibility, corrosion resistance, and good material machinability, ensuring medical-grade safety standards while effectively controlling costs and efficiency for small batches.

Q: Can material selection reduce lead times for custom turned parts?

A: Absolutely. Selecting readily available, standardized materials like 6061 aluminum can shorten procurement time by up to 50%. Using standard stock sizes also eliminates waiting for custom blanks, accelerating the overall delivery timeline for custom turned parts.

Q: How does material thermal expansion impact precision in aerospace parts?

A: High thermal expansion coefficients cause significant dimensional shifts in parts during space or high-altitude temperature cycling, affecting system accuracy and reliability. For example, satellite components often use low-expansion alloys like Invar, with a CTE below 1.5×10⁻⁶/°C, to maintain extreme dimensional stability across temperature ranges.

Q: Why partner with an ISO-certified supplier for material selection?

A: Partnering with a supplier certified to ISO (e.g., 9001), AS9100D, or ISO 13485 means their material management, machining processes, and traceability systems meet the highest international standards. This provides crucial risk mitigation for projects in critical industries like aerospace and medical, ensuring reliability from material source to final product.